Haul Truck Volume Estimation – Trayscan

CSIRO has developed a system called Trayscan to measure the in-situ volume of material contained within the tray of moving haul trucks. Such information is critical to truck utilization and can lead to significant gains in productivity. The system consists of a field computer and two proximity lasers. The lasers are placed high above the roadway to enable them to scan each truck as it passes underneath.

Although the haulage of material may seem a simple exercise, there are a number of design and scheduling issues that need to be resolved to optimize the performance of haul trucks. In particular, whilst haul-trucks are designed to carry weight, they are used to move a volume of material. The difference in function is natural. Trucks are machines that are designed to withstand mechanical load, thus maintenance engineers need to know much weight the vehicle will carry. On the other hand, mine operators, and thus contractors, are primarily interested in removing a volume of material from the ground, irrespective of its weight. The utilization of each truck can be improved by maximizing the volume of material that the tray can carry without overloading the truck. In the past, the volume carried by the truck has been inferred from a volumetric survey of the mine (divided by the number of loads) or a weight survey of each truck (bulk density of the material divided by weight). Neither technique actually measures the load in the tray and does not take into account changes in packing, or swelling, that the load undergoes in the tray. With the development of laser scanning technology, it is now possible to measure the in-situ volume of each load directly.

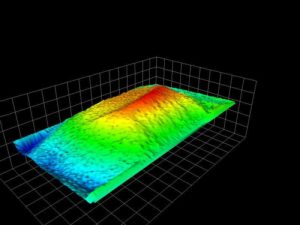

3D Scan of tray filled with coal.

Trayscan at Mt Arthur

The scanning lasers used in Trayscan are robust and eye-safe. They can operate in rain and dusty environments. The field computer consists of a ruggedized PC, with an embedded communications processor, designed and developed by CSIRO. As the truck is driven under the lasers, a 3D profile is built up. The volume can be estimated by subtracting the 3D surface of the empty tray from the 3D surface of the full tray. Although this is conceptually simple, it is computationally complex. It requires knowing the precise location and orientation of each tray and a 3D model of the empty tray. An alternative approach, developed by CSIRO, is faster, more reliable and does not require calibration. This technology has been tested at numerous mine sites (coal, iron-ore, gold etc) on over 1000 trucks. It is now technically feasible to develop a system that can operate on-line, where the volume can be transmitted to the truck, or to mine management, as it is being scanned. Such immediate feedback provides important data to the optimization of automated dispatching systems.

This system was first described and published in ACRA 2000 and commercialised in 2003 to Transcale.