Multi-Level Evolution (MLE) by Nature Machine Intelligence

Researchers from Australia’s national science agency, CSIRO, have offered a bold glimpse into what the robots of the future could look like. And it’s nothing like C3PO, or a T-800 Terminator.

In a paper just published in Nature Machine Intelligence, CSIRO’s Active Integrated Matter Future Science Platform (AIM FSP) says robots could soon be taking their engineering cues from evolution, creating truly startling and effective designs.

This concept, known as Multi-Level Evolution (MLE), argues that current robots struggle in unstructured, complex environments because they aren’t specialised enough, and should emulate the incredibly diverse adaptation animals have undergone to survive in their environment.

The paper’s lead author, Dr David Howard from the Robotics and Autonomous Systems Group, said “Evolution doesn’t care what something looks like. It searches a much wider design space and comes up with effective solutions that wouldn’t be immediately obvious to a human designer.”

“An animal like a manta ray or a kangaroo may look unusual to human eyes, but is perfectly calibrated for its environment.”

The paper argues that within just 20 years cutting edge technologies like high-throughput materials discovery and characterisation, advanced manufacturing and artificial intelligence could allow robots to be designed from the molecular level up to perform their mission in extremely challenging circumstances.

Algorithms based on natural evolution would automatically designs robots by combining a variety of materials, components, sensors and behaviours. Advanced, computer based modelling could then rapidly test prototypes in simulated, “real world” scenarios to decide which works best.

The end result would be simple, small, highly integrated, highly specialised, and highly cost-effective robots precision engineered for their task, environment, and terrain. That adapt on their own and automatically improve their performance.

One example would be a robot designed for basic environmental monitoring in extreme environments. It would need to traverse difficult terrain, gather data, and eventually fully degrade so as to not pollute the environment.

MLE’s approach to designing the robot would entirely depend on the terrain, climate and other factors.

A robot designed for work in the Sahara Desert would have to use materials that can survive punishing heat, sand and dust. It could be solar powered, slide across sand dunes, and use the harsh UV light as a trigger to eventually degrade.

The thick, low lying vegetation of the Amazon would be an entirely different challenge. A robot designed for this environment could crawl around trees and over fallen logs, be powered by biomass such as the plant matter covering the jungle floor, and degrade with humidity.

In both cases, MLE would automatically select the appropriate materials and components into a high-performing robot design, based on how well the robot performs a given task. An infinitely more scalable process than current approaches that require teams of engineers to design just one robot.

AIM FSP’s Director, Dr Danielle Kennedy, said “CSIRO is committed to leading scientific thinking and initiated this collaboration with international researchers to understand the nature of the future in robotics. The CSIRO collaborated with researchers from Vrije University in the Netherlands, the University of Lorraine in France, and Australia’s La Trobe and Monash Universities.”

“The future science platform program is part of CSIRO’s investment in creating future industries for Australia, and helping train the next generation of researchers. AIM’s focus isn’t limited to robots, we’re also exploring the future of Food, Manufacturing, Environmental Monitoring and Industrial Design.”

AIM FSP leads advances at the interface of big data, advanced autonomous systems and materials science.

- An artist’s impression of a robot for use in the Amazon. Based on tree crawling lizards and gecko, it would have articulated legs for more flexibility and climbing.

- An artist’s impression of an ocean, coastal or river based amphibious robot. It would travel in water like an eel, but have legs in order to crawl and climb.

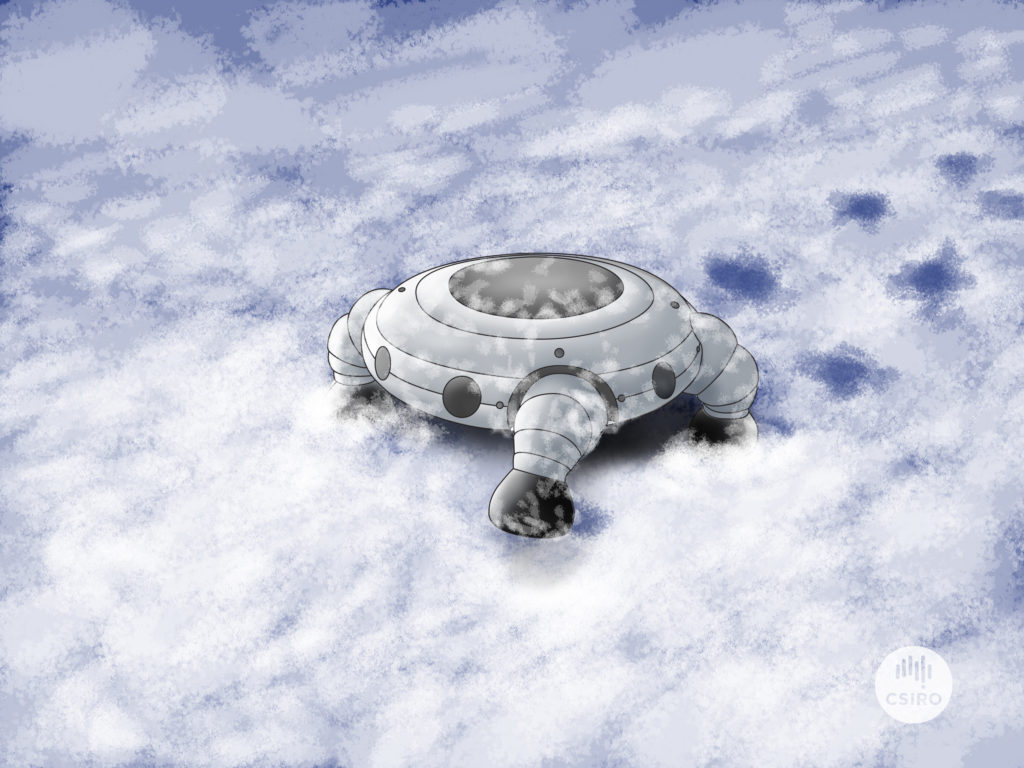

- An artist’s impression of an Antarctic based robot. Turtle like, it would be strong and robust for extreme conditions. It could also suit desert applications.

Originally published by CSIRO News on 08/01/2019.

Related media coverage

- CSIRO researchers offer look at future of robots

Our group is open to partnerships and collaborations for research, development, and commercialisation.

For more information, contact Dr David Howard.