Surface Mine Automation Framework

In May 2008 we submitted the Surface Mine Automation (SMA) framework proposal to AMIRA.

For more than two decades there has been an ongoing demand for automation technology in the mining industry. Whilst the drivers for underground and surface mining automation may differ (safety, productivity or remote operations) the failure for the substantial uptake of the technology has the same root cause: the automation systems were not able to provide integrated solutions into the mining business (i.e. enterprise-level integration). One cause for this failure was a lack of maturity in technology – which in many cases has now been addressed; the second and more serious has been a lack of leadership. Unlike a number of related industries (e.g. aviation and military in particular) the technology for the mining industry is primarily driven by the OEM’s. Whilst technically competent in their areas, the OEM’s are not always in the best position to integrate the technology into the mining business. In the aviation and military industry, the integration of technologies is moderated and certified by standards.

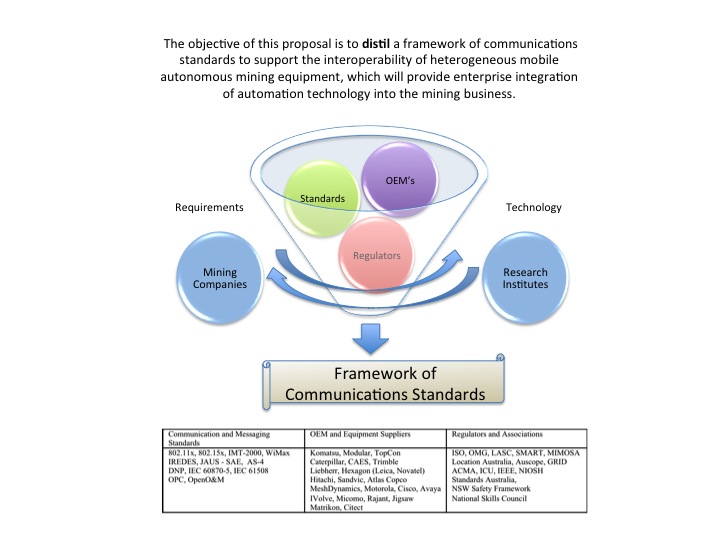

The objective of this proposal is to create a framework of communications standards to support the interoperability of heterogeneous mobile autonomous surface mining equipment, which will provide enterprise integration of automation technology into the mining business.

The scope of this framework is restricted to the automation of surface mining equipment, which includes large equipment that operates outdoors in unstructured and potentially hostile environments (i.e. Dump Truck, Excavators, Drilling and light vehicles).

This objective has a number of keywords that have specific technical consequences:

- Framework – a basic conceptual structure used to solve or address complex issues. In this case, it refers to a suite of communication standards from a number of different technology sectors that would define or describe the communications infrastructure adopted by the mine.

- Heterogeneous – the system is made up of a number of different components from different vendors.

- Interoperable – the ability of diverse systems to work together and share infrastructure. This either requires cooperation between vendors or the adoption of open standards.

- Mobile – the ability to move oneself over semi-unstructured domains. Wireless communication and localization are required for control.

- Autonomous – able to perform desired tasks without continuous human guidance. Requiring local sensing and computation (on-board computers). Autonomy has numerous safety and maintenance implications. It also poses a problem for the remote human interface (Human Factors / Immersive Interface)

- Enterprise – refers to the level of integration of Automation Technology with the Mining Business and Geospatial information systems (maintaining Business continuity)

The communications infrastructure needs to have sufficient redundant capacity and automatic management processes so that local failures do not adversely affect productivity. All personnel and manned vehicles will need to be tracked, and if autonomous vehicles fail, they must “fail to safe”, so that zero harm is maintained at mine sites. The mines will need to take ownership of their ICT infrastructure. This means that OEMs/OTMs to need to “de-couple” the communications components from their systems. Furthermore, the mines will want to take ownership of the data and information created by the equipment (fixed or mobile) that is owned by the mine operator. Action. For the mining companies (who have a list of requirements) and the research institutes (who have an understanding of the technology) to distil from the OEM’s, the standards and regulatory bodies the SMA framework.

Related Pages