Recyclable-by-Design for polymers

The challenge

Thermoset polymers and their composites are extensively applied in a wide range of industries. The long-life cycle, superior mechanical strength, and high thermal, chemical and mechanical stability have made them the best candidate for aircrafts components, wind turbines and as insulating materials in construction.

However, the crosslinked three-dimensional chemical nature of the thermoset matrix does not allow for melting by means of heat or solvent, as happens for thermoplastic matrices polymers. As a result, thermosets cannot be reshaped, recycled, or reused. This means their wide and large-scale use leads to an accumulation of thermoset waste.

Currently, there are technologies to recover thermoset polymers as fillers to be used in the same products via mechanical, thermal, and chemical recycling. However, each technique has its own drawbacks; mechanical recycling only allows for recovering lower performance reinforcements; incineration offers poor energy efficiency and generates polluting emissions; and chemical recycling is not cost-effective due to the necessity of utilising solvents, catalysts and specific conditions.

Our response

We’re aiming to design and formulate thermoset polymers that can be reprocessed or recycled.

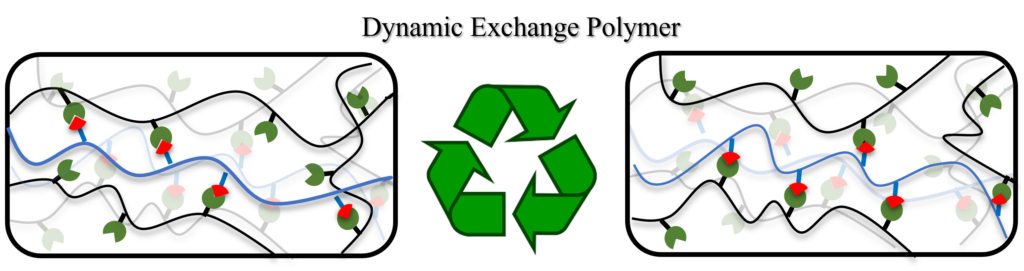

Our research is applying state-of-the-art technology to recover thermoset polymers to redesign polymers incorporating dynamic covalent bonds (DCBs). These polymers are so-called “Recyclable by design” and can be reshaped, reprocessed and recycled.

DCBs are usually based on the small reversible organic molecular reaction and can be broken/reformed to adapt a polymeric architecture upon external stimulus. By converting permanent crosslinked structures into dynamic crosslinked ones, they can de-crosslink and re-crosslink by means of exchange reactions of cleavable bonds.

The dynamic bonds arestimuli responsive to heat, irradiation, acid conditions and so on. The dynamic covalent bond strategy allows direct re-shaping and recycling/re-processing. Conventional methods employed for thermoplastic matrices, such as injection moulding or hot-press, could also be carried out for thermoset composite.

Impact

This technology promotes the circular economy and promotes new business opportunities, as the waste of low-value products is turned into high-value products. Furthermore, fibre-reinforced thermosetting composites can be recycled to replace virgin materials, reducing both the raw thermoset matrix and the raw fibres used. This lowers the environmental footprint, contributing to a more sustainable society.