The role of microalgae as a bioplastic feedstock

The challenge

More than 99 per cent of commercially available plastics are produced from fossil fuels, underscoring the need for sustainable alternatives.

Bioplastics can be made from renewable natural materials and are gaining increasing attention as a potential solution to reducing plastic waste and carbon dioxide emissions, compared to conventional plastics. Some bioplastics are produced from agricultural feedstocks that impact food security and the environment.

Microalgae are single cell organisms that need sunlight, water, carbon dioxide and some nutrients to grow, and they do not need arable land. They can be used in various ways to produce different types of bioplastics. Recent studies into microalgae show promise due to their versatility in producing bioplastics. However, not much attention has been given to different ways microalgae can be used in the bioplastic industry.

Our response

Our review study Microalgae to bioplastics – Routes and challenges explores various ways of utilising microalgae in the bioplastic industry and discusses the associated technical and economic challenges.

Our life cycle assessment study Environmental footprint of polylactic acid production utilizing cane-sugar and microalgal biomass: A LCA case study compares the environmental impacts of producing polylactic acid (a compostable bioplastic) from microalgae and sugar cane as potential alternative feedstocks.

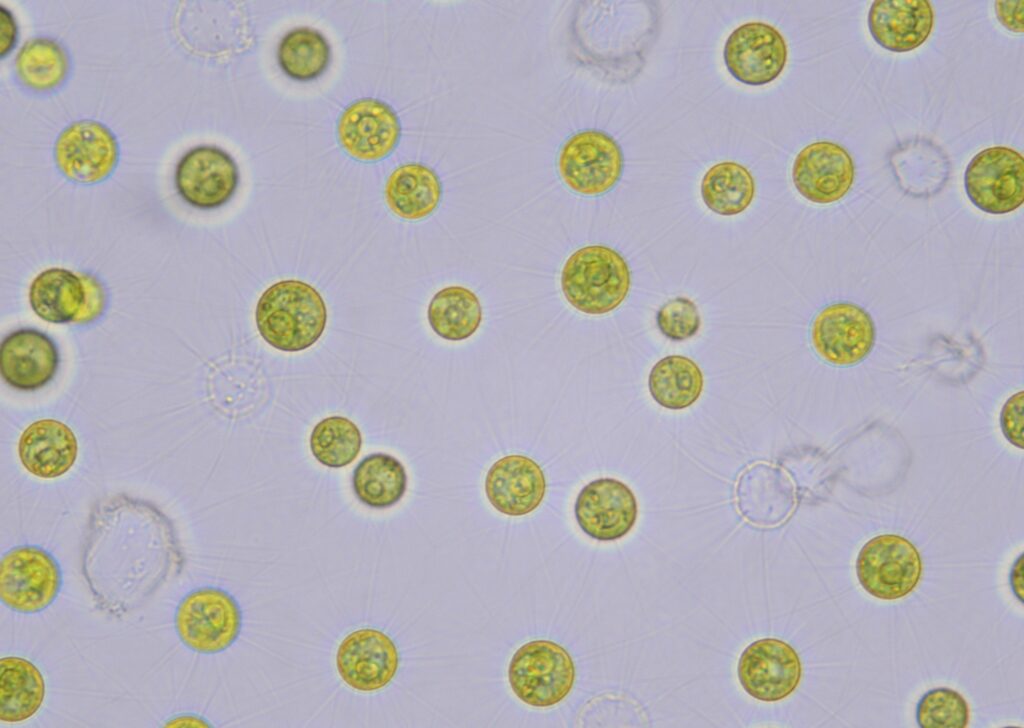

Microalgae under the microscope. Image credits Valentina Hurtado McCormick, CSIRO.

The result

Microalgal biomass is a sustainable resource for biotechnological applications and can, in principle, be produced more efficiently than plant biomass.

Microalgae biomass mainly consists of proteins, carbohydrates, lipids and nucleic acids. Under certain cultivation conditions, microalgae can also accumulate other chemicals such as polyhydroxyalkanoate and pigments.

Our review shows that microalgae can be used to produce biodegradable, compostable and drop-in bioplastics that will vary in quality, properties, applications and market price. Microalgae biomass can also be used for blending with other polymers reducing the dependency on fossil based plastics.

Optimising microalgae for bioplastic production requires careful strain selection and integration with other biotechnological applications to ensure production and to help advance the commercial viability of microalgae-based bioplastics.

Comparing microalgae with cane sugar as feedstock for poly lactic acid production, polylactic acid production from microalgae shows a higher carbon footprint than that from sugar cane due to energy intensive drying of biomass. However, the land requirements for sugar cane based PLA is significantly higher than microalgae-based alternative. Further, microalgae cultivation does not need arable land making it an accessible option for non-arable regions.

While further research is needed to refine large scale commercialisation of microalgae-based bioplastics, there is significant promise in this innovative pathway in expanding bioplastic options.

For more information on bioplastics, we have produced the State of Bioplastics in Australia Report to better understand bioplastic materials and their integration in Australia’s waste streams.