PETase enzymes

The challenge

The use of plastic materials has spread to all industries and manufactured products given their outstanding mechanical properties, malleability, thermal and chemical stability and low price. Most plastics are very difficult to degrade, which is good for storage, packaging and durability of the products, but hampers disposal and recycling of the material.

The intended useful life of plastic packaging is about one year. However, 95 per cent of packaging material value is discarded after a single use. Plastic packaging that leaks into the environment can persist for hundreds of years, slowly decaying to microparticles that can enter the food chain and constitute a serious health threat for marine life and humans.

Because of its ever expanding use, plastic debris in our oceans now accounts for an estimated 80 per cent of marine litter.

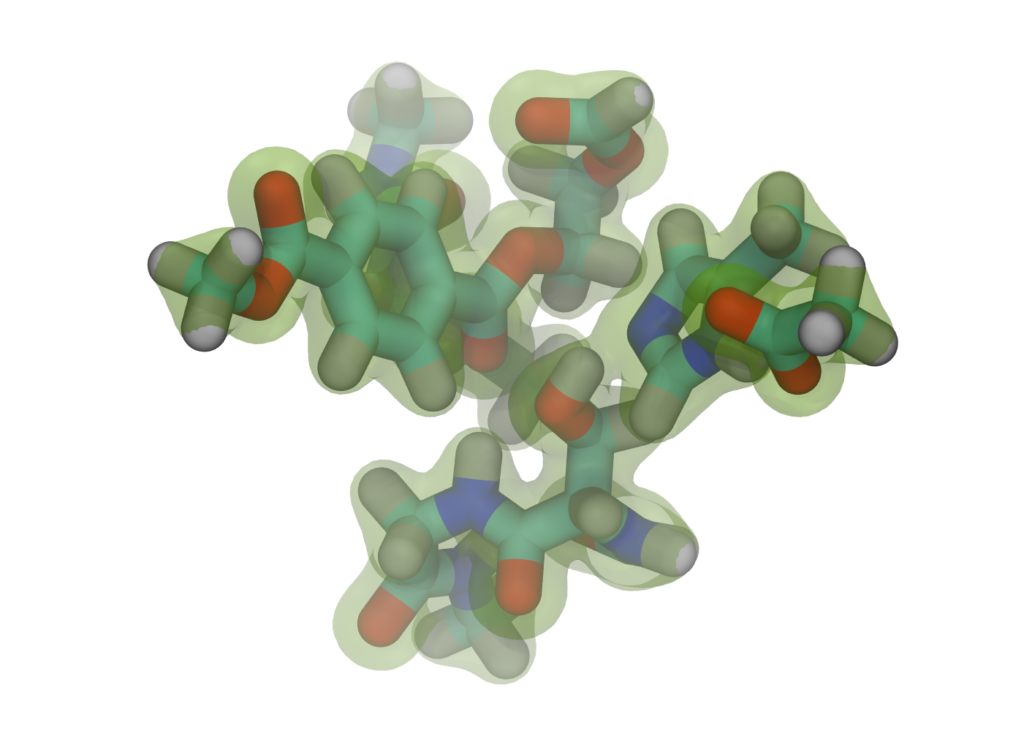

Computational model of the active site of a plastic degrading enzyme. The residues and the substrate are represented in liquorice, the electron density is represented as a transparent surface.

Packaging recycling rates have stagnated, and there are several gaps in plastic packaging collection, recycling and reprocessing. Australia and Asia are both affected by plastic pollution. This provides a strong need for technological solutions that can be applied worldwide.

Our response

Several enzymes have been found to degrade certain plastics but the low turnover and low thermostability hinders their use for industrial and recycling applications.

By using computational modelling and structure-based rational design we are engineering new enzymes that can degrade (by depolymerization) various plastic polymers in biotechnological applications. The cornerstone of rational protein design is to predict the effect of each residue on the enzyme’s biochemical and biophysical properties.

Impact

We are working to tune the enzymes for a range of substrates and applications, from degrading microplastics in waterways to upcycling plastic waste (i.e. create a product of more value) in recycling facilities.

Enzymatic depolymerization breaks down the plastic material to its constituent monomers. By recovering these building blocks of the polymer we can rebuild the full value and quality of the original material in a way that is efficient and environmentally responsible.