Electro‑separation innovation for high‑efficiency ammonia recovery from waste streams – A circular economy initiative

The Challenge

Ammonia (NH₃) is emerging as a critical component in the global transition to renewable energy due to its high hydrogen content, established transport infrastructure, and potential for carbon-free energy production. However, conventional ammonia synthesis via the Haber-Bosch process is energy-intensive and a major contributor to global greenhouse gas (GHG) emissions.

Concurrently, ammonia pollution in wastewater presents significant challenges for utilities and the environment. Its removal can account for up to 80% of the energy used in wastewater treatment, making it the most energy- and cost-intensive step. Biological treatment methods also result in GHG emissions such as nitrous oxide (N₂O) and nitrogen oxides (NOx)—both far more potent than CO₂ in driving climate change.

Despite these issues, wastewater streams—particularly centrate from anaerobic digestion—often contain high concentrations of ammonia (500–1000 mgNH₃-N/L or more), representing a valuable resource currently lost to the environment. However, these streams also contain high levels of inorganic salts and organic compounds, which increase the risk of membrane fouling and reduce recovery efficiency using conventional separation technologies.

There is a clear need for an efficient, low-emission, and scalable solution that enables the recovery and reuse of ammonia, in line with circular economy principles.

Our Response

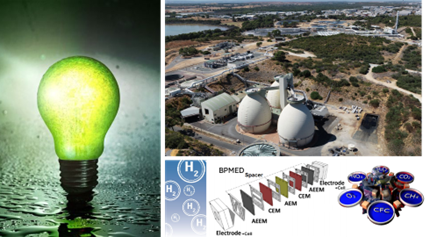

To address this challenge, CSIRO developed an innovative solution using Bipolar Membrane Electrodialysis (BPMED) — a cutting-edge technology that recovers ammonia from wastewater using electricity only, with no chemical additives and no direct greenhouse gas emissions. This approach transforms a pollutant into a valuable product, enabling its reintegration into industrial, agricultural, and energy systems.

Key activities included:

- Designing and operating a BPMED prototype system for ammonia recovery from real centrate streams.

- Optimising BPMED configuration to maximise nitrogen recovery with minimal energy input.

- Evaluating fouling control strategies to extend membrane life and improve system reliability.

- Quantifying the energy performance of BPMED compared to conventional ammonia removal and production processes.

- Investigating end-use options for recovered ammonia — such as fertiliser production, green hydrogen storage, and low-carbon fuels — helping close the loop between waste and resource.

This project exemplifies a circular economy approach, shifting the focus from “pollutant removal” to “resource recovery”, enabling utilities and industries to extract value from waste while reducing environmental impacts.

The Results

The project demonstrated that BPMED is a technically and economically viable method for recovering ammonia from complex wastewater matrices such as anaerobic digester centrate.

Key outcomes included:

- Achieved 85–91% ammonia recovery from real centrate streams with low energy consumption, outperforming conventional biological and chemical processes.

- Successfully produced concentrated ammonia solutions (ammonium hydroxide) using electricity alone, without chemical reagents.

- Developed and validated effective pre-treatment strategies to reduce membrane fouling and improve system durability.

- Showcased a robust pathway to transform waste nitrogen into high-value, reusable products.

- Aligned system design and outputs with circular economy goals, enabling the reuse of recovered ammonia in fertilisers, clean fuels, and green chemicals.

These results highlight the potential of BPMED to deliver both economic and environmental benefits. It enables cost-effective and energy-efficient wastewater treatment, reducing operational costs for utilities while supporting the growth of a sustainable ammonia/ hydrogen industry through local production from waste streams. By turning a pollutant into a resource, the technology advances circular economy models and creates new value chains.

Environmentally, BPMED reduces GHG emissions by avoiding N₂O and NOx typically produced in biological ammonia removal processes. It improves effluent quality through more effective nitrogen removal, and facilitates the use of green ammonia as a clean fuel and chemical feedstock, contributing to Australia’s decarbonisation objectives.

With the technology’s feasibility established, our next steps include:

- Pilot-scale deployment of BPMED with industry partners and water utilities.

- Enhancing nutrient recovery by capturing phosphate, calcium, magnesium, and sulfate during treatment.

- Advancing commercialisation strategies, with a focus on agriculture, meat processing, and industrial wastewater sectors.

- Exploring policy, regulatory, and market pathways to integrate recovered ammonia into Australia’s circular bioeconomy and clean energy roadmap.

Contact for further information: Sebastien Allard (sebastien.allard@csiro.au)